Projects

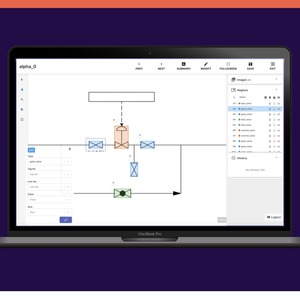

Engineering Diagrams Data Extraction

In this project, we use computer vision and deep learning technology to enable automatic detection and recognition of symbols and text from piping & instrumentation (P&ID) and other engineering diagrams. This method is able to label any symbols in tens of drawings in minutes and export the results in Excel or CSV format. The text recognition feature enables the search feature to rapidly find text in drawings.

View Project

Fashion Visual Search

The fashion visual search turns customer's inspiration into product discovery by removing the barriers of textual search, using AI to understand the context of images and return a list of related results. It consists of three components. First, it detects and classifies clothing items in the image. It uses Mask R-CNN to do this task. Second, it extracts high-level features and representation of detected clothing items using ResNet architecture. Third, the generated features are compared to the database of features (i.e. database of clothing images) for retrieval.

View Project

Non-Deep-Learning Grocery Product Classification

Using deep learning to classify grocery products can be overwhelming, considering the variety of the products and the amount of data needed to train the alogorithm. This project uses OpenCV's feature detection and description (e.g. SHITOMASI, HARRIS, FAST, ORB, BRIEF, FREAK, AKAZE, SIFT, BRISK) to perform classification of grocery products. Using this system, a product image is enough as a reference to recognize the product. The product packaging shall be distinct in order for the system to perform correct classification.

View Project

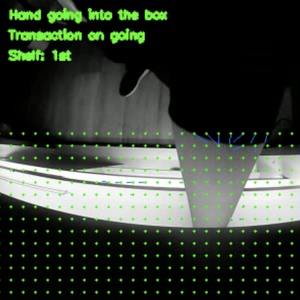

Hand Direction and Location Identification

This system is the first iteration used for identifying the direction and location of hand that goes in and out GetGO Bar. This system is one of the components that construct automated transaction system that have the function to recognize customer activities during the transaction with GetGO Bar. This system utilizes two downward-looking cameras that produce video streaming during a transaction. To identify hand direction, we use the Gunnar-Farneback optical flow. To identify the location of the hand (in which shelf the hand is located), we use background subtraction method.

View Project

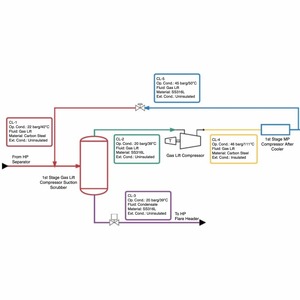

Automated Corrosion Loop Development

This software implements the paper "Corrosion loop development of oil and gas piping system based on machine learning and group technology method" (see the paper here). The aim is to develop an automated corrosion loop development system based on k-means clustering and group technology method. This system is expected to reduce the man-hours required develop corrosion loops.

View Project

Lane Lines Road Detection

A computer vision algorithm to detect lane boundaries in a video. This project uses camera calibration, perspective transformation, gradient and color thresholding, and curve fitting to identify road lane boundaries and its radius of curvatures from a stream of videos.

View ProjectCollision Avoidance System

This project develops car collision avoidance system by using Lidar measurements and images from camera. First, we develop a way to match 3D objects over time by using keypoint correspondences. Then, we calculate Compute Time-To-Collision (TTC) based on Lidar measurements. We then proceed to do the same using the camera, which requires to first associate keypoint matches to regions of interest and then to compute the TTC based on those matches.

View Project

Motion Heatmap

Motion heatmap is useful to see movement patterns over time. For example, it could be used to see the usage of entrances to a factory floor over time, or patterns of shoppers in a store. The application applies background subtraction to create a mask. A threshold is then applied to the mask to remove small amounts of movement, and to set the accumulation value for each iteration. The result of the threshold is added to an accumulation image, which is what records the motion. At the very end, a color map is applied to the accumulated image so it's easier to see the motion. This colored imaged is then combined to accomplish the overlay.

View ProjectView More Projects on Kaggle